Why Is There No Talk of Takata’s SSI-20 Side Impact Inflator?

by Kevin Fitzgerald on May 4, 2021

Takata designed and manufactured only one ammonium nitrate (PSAN) side impact inflator called SSI-20. There are various applications for this type of device, but they are predominately used for thoracic protection in side collisions and are located either in the door panel or buried in the seatback.

Europe produced nearly 20 million non-desiccated SSI-20s beginning in 2008, many of which found their way to the U.S., and for some inexplicable reason, none have been included in the massive recall. Twelve million desiccated SSI-20s were assembled in Monclova, MX for GM and that version was identified and protected under NHTSA’s May 2020 ruling that excluded Takata’s desiccated inflators from remediation. No SSI-20 has ever been included in the Takata recalls and that is a dangerous mistake.

This article is meant to awaken the driving public to the danger this inflator presents and begs the question as to why the National Highway Traffic Safety Administration (NHTSA) has not initiated its recall, desiccated or not.

The following excerpt is lifted from NHTSA’s Coordinated Remedy Program Proceeding, What is the status? (Part II) Scott Yon, dated October 2015.

While we have been gathering information in the Coordinated Remedy Proceeding, we have also continued our normal work in our ongoing investigation of the Takata inflators. During that investigation, the agency has learned of a new potential safety concern involving an air bag inflator Takata produces that has not been included in any of Takata’s recalls, though some vehicle manufacturers are recalling parts. This additional inflator, called an SSI-20, is primarily used in side air bags and has been added to our investigation.

Since June of this year (2105), both General Motors and Volkswagen have reported SSI-20 rupture incidents to the agency. Currently, General Motors has a recall for 395 model year 2015 vehicles. Those vehicles, all model year 2015, are the Buick Lacrosse, the Cadillac XTS, the Chevrolet Camaro, the Chevrolet Equinox, and the Chevrolet Malibu.

The VW Tiguan Rupture

On June 7, 2015, a MY15 Volkswagen Tiguan was struck by a deer triggering the vehicle’s SSI-20 side airbag. Instead of deploying normally, the airbag’s inflator ruptured, throwing shards of metal into the cabin that injured the driver. The defective part was manufactured on Takata’s fully automated SSI-20 assembly in Frieberg, Germany.

VW first learned of the incident on June 17th and met with Takata four days later where they were surprised by to hear of two earlier ruptures of the inflator that had gone unreported. Over the course of the next few weeks, the number of undisclosed failures grew to eight all taking place between May and June of 2015. An additional GM rupture, which occurred on July 3rd during a lot acceptance test (LAT) in Monclova, was also reported to VW as part of the investigation.

It was an SSI-20 rupture bonanza. A time for NHTSA to really dig in, but the root cause investigation played out in typical Takata fashion, assigning the failures to a manufacturing error that resulted in low density propellant. NHTSA concurred, grouping the failures together, and issuing a limited recall of only 1100 parts, successfully whitewashing yet another Takata issue. The truth is the SSI-20 is one of the most unstable devices Takata ever produced because in addition to its PSAN threat, the inflator possesses a critical design flaw – one Takata has known about since 2009 when the ruptures first started.

SSI-20 Design Description

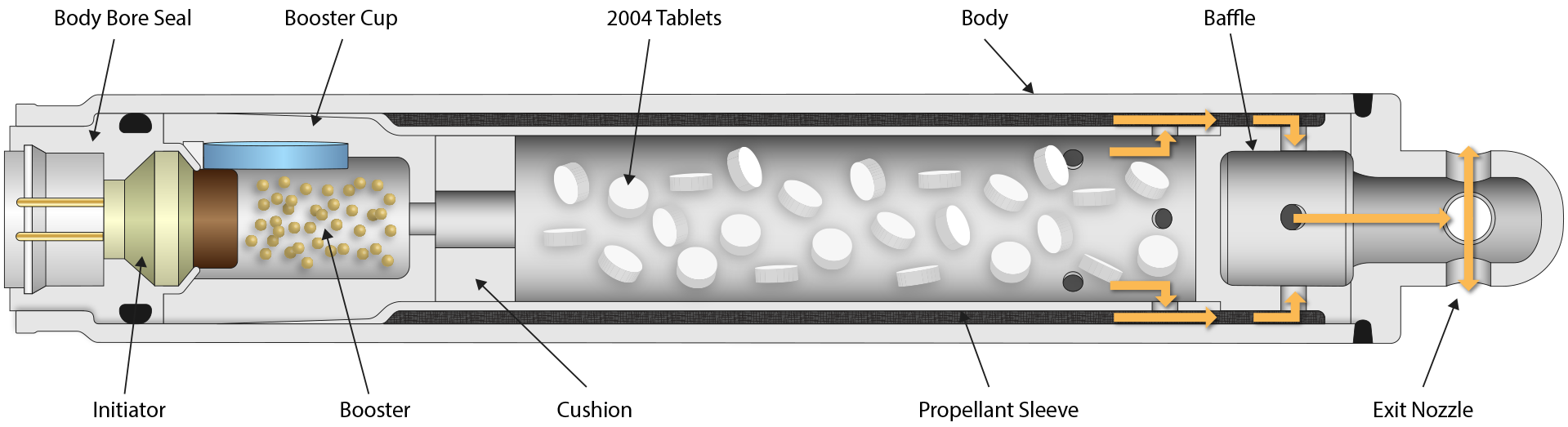

Presented below is a cross section of the SSI-20 inflator, labeling all the key internal components that will be used to further the discussion.

What follows next is a short description of how the inflator functions. Upon impact, the vehicle’s electronic control module sends a signal that fires the initiator which in turn ignites the 3110 granular booster. The output of the booster spews hot gas and particulate into the PSAN tablet bed providing both the spark and pressure needed to bootstrap combustion. As gas is produced, it first passes through multiple holes in the propellant sleeve, where it then turns and runs down the annulus between the sleeve and body. When it reaches the baffle, it is turned again and then once more before it exits through the inflator exhaust ports.

The Critical Flaw

The SSI-20 does not have a filter to trap the particulate produced when its solid propellant is converted to gas. Takata’s PSAN is highly efficient, meaning it generates only a fraction of solids upon combustion, about 4%. Since the amount of propellant in the SSI-20 is small to begin with, very little particulate is generated, and it is trapped by the multiple turns the gas takes to exit the inflator, or what is referred to as a ‘torturous path.’ Gas can turn corners, but solids have momentum, and with each turn, they dead-end and plate on the inflator’s interior surfaces. The particulate that does manage to escape is always well within customer specifications. The removal of the filter allowed Takata to reduce the inflator’s diameter to 20 mm, the smallest on the market.

That brings us to the critical design flaw. The SSI-20’s small diameter may have made for a great sales pitch, but it came with serious consequences that Takata didn’t discover until after the inflator was in production. At such a small a diameter, the output of the initiator and 3110 booster produces a nasty piston effect on the propellant column. This was first discovered after a rupture of a GM SSI-20 during an LAT in Monclova in 2009 that went unreported by Takata and is not included in the failures discussed above. As part of that failure investigation, inflators produced immediately before and after the anomaly were dissected to look for clues, revealing that up to 30% of the tablets were being cracked during assembly. Yes, a manufacturing error, but the investigation uncovered more.

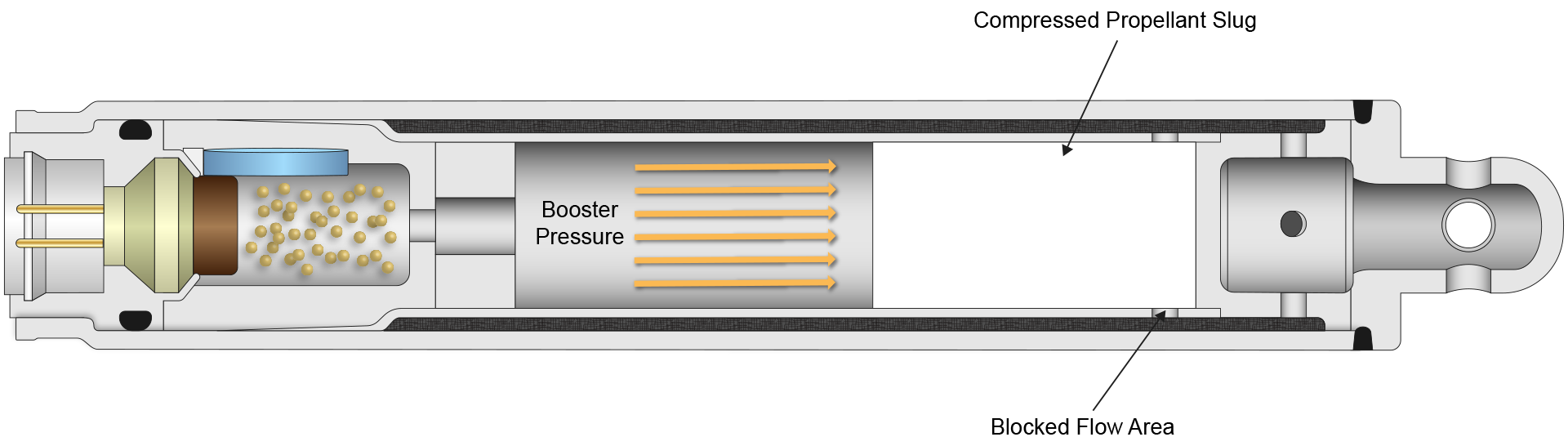

The cracked tablets essentially act as additional booster, so another experiment, called a snuff test, was conducted to determine the effect of added ignition material on the propellant column. Large holes were drilled in the inflator’s propellant sleeve and body to let the initial gases escape, preventing combustion from bootstrapping – the event quenches. Once deployed, the inflator can be disassembled, and the condition of the propellant inspected. A good snuff test would show the tablets intact and uniformly regressing. A bad snuff test would show them in pieces, signaling an uncontrolled combustion process with variable output. The test results were frightening. An evaluation with no cracked tablets was conducted first, and the heat and pressure from the ignition event was so overwhelming it transformed the tablet column into a single slug that covered most of the propellant sleeve exits holes (see below). There were no tablets to inspect. With most of the holes blocked by design, adding cracked tablets only amplified the problem and occasionally led to rupture. There was absolutely no margin for error, something Takata was prone to.

Again, all this occurred in 2009 and GM was never informed. A propellant bed height check was added to the process to avoid cracking tablets, but the effects of the propellant slug went unresolved. It became a de-facto part of the design and no further studies were conducted to determine just how close to the edge the inflator was. That is until the Tiguan accident when some Takata engineers dug deeper than the canned response and picked up where the 2009 investigation left off.

If the bed height check was functioning as designed, then there had to be a reason other than cracked tablets for the string of ruptures. While management assembled their story, engineers searched for answers. What could be causing the propellant bed compaction to suddenly intensify and lead to this many ruptures? Fault trees pointed to the foam cushion located between the booster cup and propellant column that was used to take up assembly tolerances. The cushion had a hole through its center to allow for immediate gas delivery and the investigation found that if the hole were missing or too small, the piston effect worsened, and the rupture rate soared to a shocking 50%! NHTSA and the automakers were informed, but the public facing story remained a propellant manufacturing error.

A vision system was added to the assembly line to inspect for the cushion through-hole which doused the immediate flare up, but again did nothing to resolve the underlying issue. The propellant column was still being converted into an uncontrolled, sometimes dangerous slug, flirting with catastrophe. The only difference this time was that everyone involved knew it.

Wrap Up

It’s not clear why NHTSA excluded the un-desiccated SSI-20 inflator from the original recall, but the agency’s willingness to look the other way concerning the inflator’s serious design flaws makes it clear they want to keep it that way. Like every Takata PSAN inflator, the SSI-20 will eventually succumb to time in the field, and yes, the non-desiccated version should be recalled immediately, but framing the discussion around whether the inflator has desiccant or not is misguided. The critical flaw doesn’t care. Those without desiccant should just go to the front of the recall line and those with desiccant to the back.

The real reason these airbags are not under recall is greed. Most are buried in seats and their replacement will come at an astronomical expense. NHTSA has simply forgotten that it is us they are supposed to be fighting for at all costs.

Ronald Silich

May 27, 2020 at 12:45 pm

I am a field courier for the removal and collection of affected Takata airbags from Auto Recyclers in Australia and to date there has been no discussion regarding side airbags. Which begs the question of what are the lives of people Down Under valued at and how long will it be before our governing body the ACCC wakes up recalls these ticking time bombs also.